Institut Charles Sadron News

Publié le 10/03/2023 par Drenckhan Wiebke

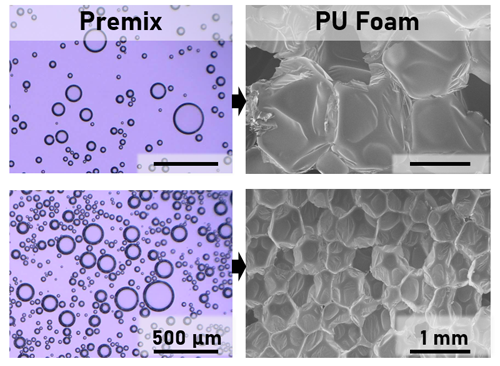

The interest in polyurethane rigid (PUR) foams as potent thermally insulating materials continues to grow as the minimization of CO2 emissions has become a global issue. Controlling the thermal insulation efficiency of PUR foams starts with the control of their morphology. Although the presence of micrometric air bubbles originating from air entrainment during the blending of the PU reactive mixture has been shown in the past to influence the final PUR foam morphology, detailed experimental investigations on how exactly they affect the final PUR foam pore size are still lacking. To fill this gap, the MIM team of the ICS in collaboration with BASF developed a new experimental method based on a double-syringe mixing device. This method allows to control the number of micron-sized bubbles generated during a first air entrainment step, before the same device is used to blend the reactive components in a sealed environment. Using this method, the researchers could correlate quantitatively the changes of the final PUR foam morphology with the variation of the air bubble density in the initially liquid reactive mixture. Their results confirm recent findings which suggest the presence of two different regimes of bubble nucleation and growth depending on the presence or absence of dispersed air bubbles in the premix. This new study pushes those insights further by demonstrating an inverse relation between the air bubble density in the liquid reactive mixture and the final pore volume of the PUR foam. For example, at constant chemical formulation and blending conditions, the final pore size of the foam could be reduced from 1600 to 400 ?m simply by increasing the amount of pre-dispersed air bubbles in the premix. The researchers are confident that the presented approach will not only provide a valuable experimental technique to scan formulations in R&D laboratories, but it will also provide suggestions for the optimization of industrial processes. Ce travail a été publié dans le "Journal of Cellular Plastics".